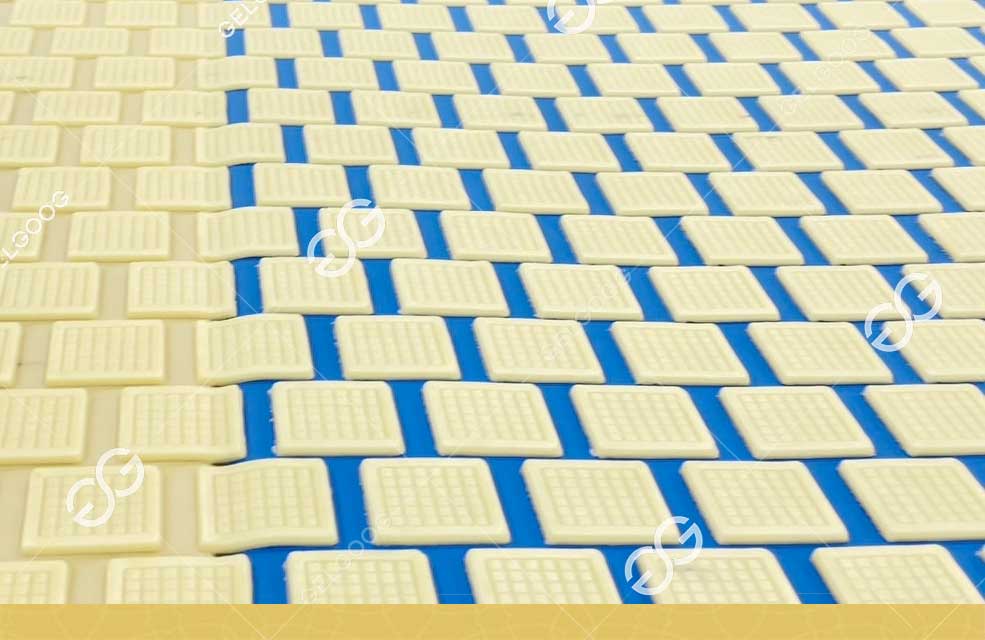

GELGOOG designs and manufactures high-speed, automated compressed biscuit production lines for global food manufacturers. Our integrated biscuit making machinery seamlessly handles the entire process from dough mixing to packaging, ensuring superior output, consistent quality, and a rapid return on your investment.

Our production line is optimized for large-scale production, combining traditional processes with modern automation for unmanned and highly efficient operation.

Our compressed cookie manufacturing equipment is ideal for the following types of businesses:

Large-scale snack cookie and energy bar manufacturers

Existing food processing plants seeking product diversification or capacity upgrades

Q1: What is the capacity and floor space required for a standard production line?

A: We offer various configurations. Specific dimensions can be customized to your factory layout.

Q2: Does the equipment meet international safety and hygiene standards?

A: Yes. Our equipment is designed to meet standards such as CE and ISO 22000 (Food Safety Management System) and can assist in adapting to the regulations of the target export country.

Q3: Do you provide installation and technical support?

A: Of course. We provide global installation supervision, operator training, and 24/7 remote online technical support. We also provide a comprehensive spare parts list.

Q4: What is the minimum order quantity and delivery time?

A: We mainly supply complete production lines. The delivery time for a standard production line is typically 60-90 days, depending on the configuration and level of customization.

We understand that every factory's needs are unique. Please tell us your specific requirements, and we will tailor the best solution for you.