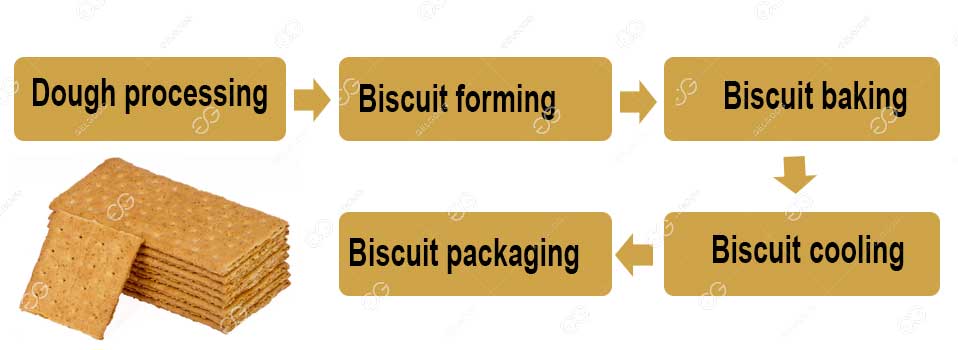

What is a Complete cracker production line composition chart? From dough processing to packaging, and other processes that may be involved in the production line.

In this blog post, we will explain the detailed factory production process one by one.

1:Dough processing: The process starts with dough processing. To produce a uniform dough, high-quality flour, water, salt, and other ingredients are precisely mixed. Specialized dough mixers ensure the right texture and consistency.

2:Forming process: Common methods include extrusion, sheeting and molding.

In extrusion, the dough is forced through a die to form a continuous shape. In sheeting, the dough is flattened into a thin sheet. This can then be cut into the desired shape.

Molding is used for cookies with specific shapes and designs.

3:The baking stage: Crackers are arranged in an industrial oven and baked at a predetermined temperature for a set duration. Tunnel ovens, which facilitate a continuous product flow, are commonly utilized in cracker production. The crackers are conveyed through the oven on belts, ensuring an even baking process.

4:The cooling phase: This stage is crucial as rapid cooling might lead to cracks or brittleness in the crackers. Therefore, a gradual and controlled cooling is necessary. The crackers are cooled on a conveyor belt to prevent the build-up of moisture.

5:Packaging concludes the process. Automated machines wrap the crackers in airtight bags or boxes to maintain their freshness and prepare them for shipping.

Supplementary Processes:

Beyond the primary steps, the full complete cracker production line composition chart also incorporates additional processes to enhance the flavor of the crackers. These include:

In summary, a cracker production line composition chart encompasses dough preparation, shaping, baking, cooling, and packaging. Each stage is meticulously managed to ensure that consumers receive crackers of the highest quality.