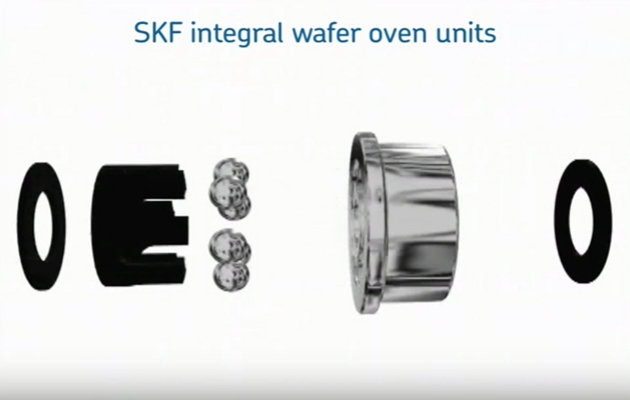

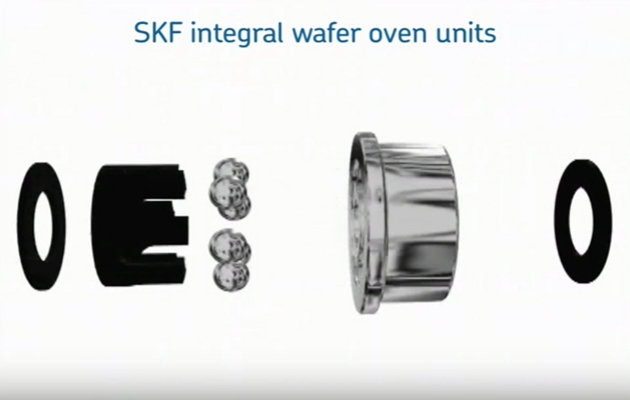

Integral Wafer Oven Units for Wafer Biscuit Making Plant

Recently, there are a new technology about maintenance the wafer biscuit oven for prolong the usage time of the wafer biscuit making plant, many businessmen try to use to this SKF wafer biscuit oven to their biscuits making factory. This technology always be used in wafer biscuit oven of the whole plant.

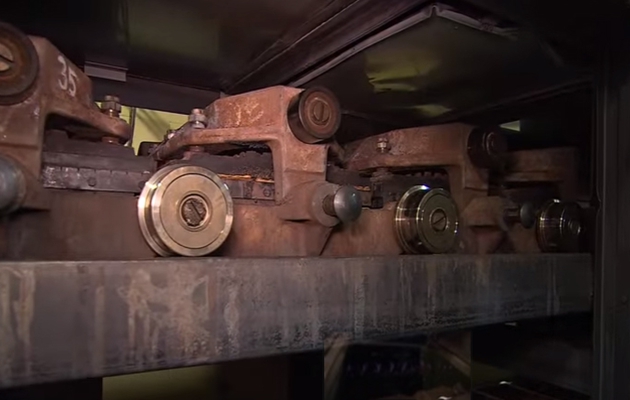

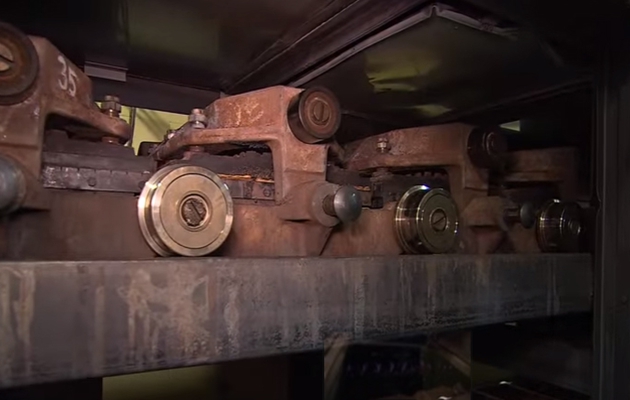

Actually, many wafer biscuit ,making factory will stop producing wafer biscuits every sixtheen weeks to check the machines, and at the same time a lot of expensive food grade greases will put into machines which can keep these machine working normally. So in other words, the wafer biscuit making factory will have lost money duce to they stop abpouot 26 hours to producing wafer biscuits. The production will also be affected by bearing bearing grease temperature limits, the machine does not allow higher temperature in the making process. That's will improve the maintenance costs, not good for wafer biscuit making factory. The SKF can offer the grease-free solutions and imporve the capacity og the wafer biscuits. The oven is upgraded by installing with SKF High Temperature Wafers oven bearing unit. No lubrication and can be operated at higher temperatures.

Advatange:

1. The upgrade to the SKF unit will help manufacturers to increase productivity and eliminate the 8-day downtime which used to repair the travel wheel and upper roller position each year.

2. 5 years without lubrication, all-weather work.

3. Reduced operating costs and environmental friendly.

4. Easy to install again and fast.

Add New Comment